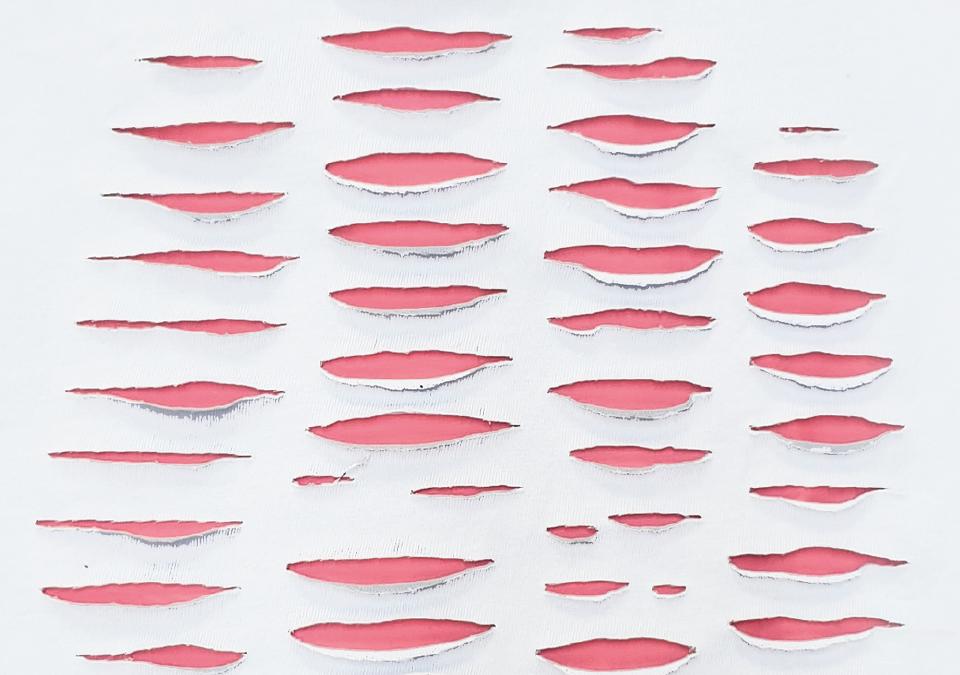

Fabric laser cutting

A cutting-edge technique

Fabric laser cutting is a technique known for its precision and flexibility, it is composed of a laser beam that melts the material during cutting, thus obtaining clean, precise and perfectly sealed edges. This technique gives the garment a very pleasant finish to the eye and to the touch and is used on almost all fabrics, from cotton, to silk, from nylon to denim*.Fabric laser cutting

This innovative technique allows you to cut fabrics and garments much faster than you can do through the use of a simple blade, increasing the productivity and efficiency of the entire production process. The lack of direct contact with the material and the absence of the use of tools guarantees a very high quality of workmanship and free from defects or inaccuracies.Strength points

Simple, efficient and fast, the advantages of fabric laser cutting are the following:- perfectly sealed hems;

- no presence of fraying or seams;

- accuracy, productivity and speed in processing;

- elimination of blade fixing times, as it is not foreseen in direct contact with the material;

- high quality workmanship with a pleasant finish to the touch and to the eye;

- a single tool to create all shapes, geometric and otherwise.

A revolution that has already been written

An innovative, different and extremely beautiful technique. Through the fabric laser cutting you will be able to create processes, details or entire collections supported by a technique that has no constraints, free and versatile, to make yourself recognized on the catwalk.*If the material you intend to laser is not traditional, our in-house team of highly specialized craftsmen will carry out various feasibility tests on your material to ensure the success of the processing.

Could you recognize the fabric laser cutting technique? Check out ours Perspective Bucket and find out which processing uses this technology

Contact us to receive further information about this technique, to submit your idea or just to know our reality.